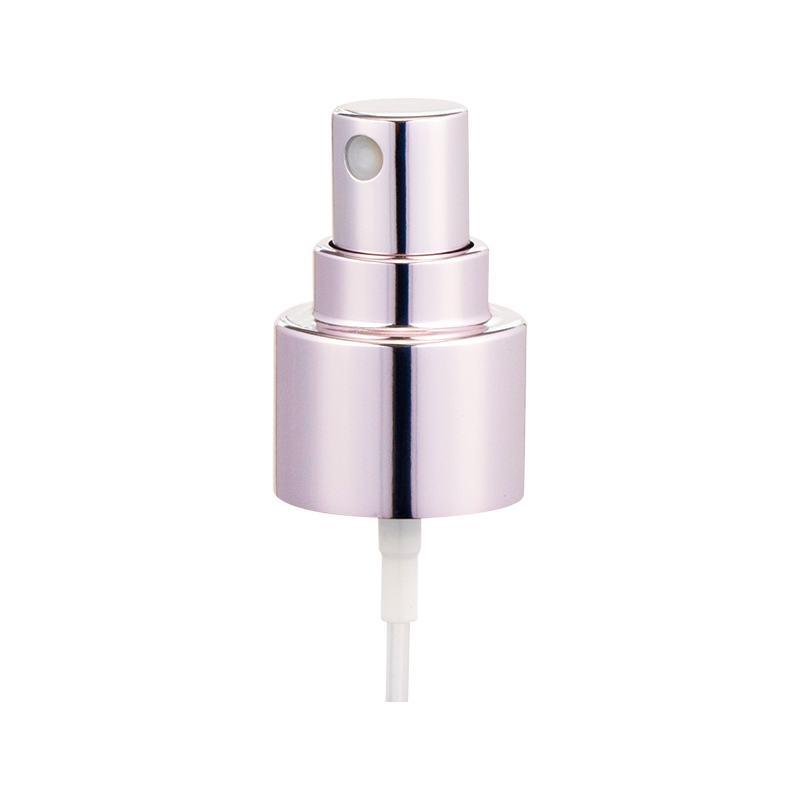

Electrochemical Aluminum Mist Spray Pump

When it comes to cosmetic packaging, the cosmetic plastic cover is often a "behind-the-scenes hero" that’s easy to overlook—but its role in the entire product lifecycle is far more critical than many realize. For consumers, a well-designed cosmetic plastic cover is the first line of defense for their favorite beauty products: it seals in the freshness of liquid formulas (like serums or lotions) to prevent oxidation, keeps dust and contaminants out of powdered products (such as blushes or loose powders), and ensures no leakage during travel or daily use. For cosmetic brands and manufacturers, the cosmetic plastic cover is also a key part of user experience and product integrity— a poorly fitting or low-quality cover can lead to customer complaints, product waste, and even damage to brand reputation.

In recent years, the market’s attention to cosmetic plastic covers has grown significantly, driven by two main trends. First, there’s a rising focus on safety. With more consumers prioritizing ingredient transparency and packaging safety, the materials used in cosmetic plastic covers have come under scrutiny. Brands and buyers now seek covers made from food-grade or cosmetic-grade plastics (such as PP, PET, or PE) that are free from harmful substances like BPA, ensuring no chemical transfer to the product inside. This focus on safety has made "material compliance" a core consideration when developing or selecting cosmetic plastic covers.

Second, practicality and user-centric design have become key differentiators. Today’s consumers don’t just want a cover that "works"—they want one that’s easy to use. For example, a cosmetic plastic cover with a non-slip texture is more convenient for users with wet hands (common when applying skincare products in the bathroom), while a lightweight yet durable cover is preferred for travel-sized cosmetics. Additionally, as sustainability gains traction across the beauty industry, there’s growing interest in eco-friendly cosmetic plastic covers—such as those made from recycled plastics or biodegradable materials—that reduce environmental impact without compromising functionality.

This article will dive deep into the world of cosmetic plastic covers, exploring their key types (from basic plastic cosmetic lids to specialized cosmetic bottle plastic covers), practical selection criteria, and the latest design and material innovations. Whether you’re a consumer looking to understand how to choose high-quality cosmetic packaging or an industry professional focused on optimizing product design, this guide will shed light on why the humble cosmetic plastic cover is so essential to the beauty ecosystem.

The term "cosmetic plastic cover" encompasses a diverse range of designs, each tailored to meet the unique needs of different cosmetic products, usage habits, and consumer preferences. From sealing loose powders to protecting liquid serums, the right type of cosmetic plastic cover not only preserves product quality but also enhances the overall user experience. Below is a detailed breakdown of the core types of cosmetic plastic covers and their typical application scenarios, including key variants like plastic cosmetic lids and cosmetic bottle plastic covers.

As one of the most common forms of cosmetic plastic covers, the "plastic cosmetic lid" is designed primarily for solid or powdered cosmetic products that require a secure, easy-to-open seal. Its structure is often simple yet functional: most feature a snap-on or screw-on design to ensure tight closure, while some add soft gaskets inside to boost dust and moisture resistance.

The plastic cosmetic lid excels in simplicity and cost-effectiveness, while its versatility makes it compatible with a wide range of small to medium-sized cosmetic containers. Its easy-to-manufacture design also allows for subtle customizations, such as matte finishes or embossed patterns, without increasing production complexity.

Unlike plastic cosmetic lids (which focus on solid products), "cosmetic bottle plastic covers" are engineered specifically for bottle-shaped cosmetic containers—addressing the unique challenges of storing liquids, gels, or aerosols (e.g., preventing leakage, controlling dispense volume). These covers often integrate additional components (like pumps or droppers) to match the product’s viscosity and usage needs.

The cosmetic bottle plastic cover’s biggest strength is its adaptability to liquid products. By integrating functional components (pumps, stoppers, wands) directly into the cover, it streamlines usage while ensuring product safety—avoiding spills, contamination, or premature spoilage.

"Transparent cosmetic plastic covers" stand out for their use of clear or semi-transparent plastic materials (such as high-impact polystyrene or clear PP), which prioritize visibility—allowing consumers to see the product inside without opening the cover. This design not only enhances convenience but also leverages the product’s color or texture as a marketing tool.

Beyond visibility, transparent cosmetic plastic covers offer excellent durability—most are resistant to scratches and yellowing (thanks to anti-UV additives), ensuring the cover remains clear throughout the product’s lifecycle. They also pair well with other design elements (like labels or embossing) to balance functionality and aesthetics.

While terms like "plastic cosmetic lid" or "cosmetic bottle plastic cover" refer to single-container covers, "cosmetic packaging covers" are a broader category—encompassing plastic covers designed for multi-product sets, gift boxes, or large-format packaging. These covers prioritize protecting the entire ensemble while maintaining a cohesive look.

The cosmetic packaging cover’s main value lies in its versatility for ensemble products. It unifies the packaging’s appearance, protects multiple items at once, and can be tailored to different sizes—from small gift sets to large bulk containers.

In daily consumer language, "plastic makeup cover" is often used interchangeably with "cosmetic plastic cover"—referring to any plastic cover used for makeup or skincare products. Its design prioritizes ease of use and compatibility with everyday scenarios, making it a staple in most people’s beauty routines.

The plastic makeup cover’s strength is its accessibility—it’s designed for everyday use, with no complex features, making it intuitive for all consumers. Its affordability and durability also mean it can withstand frequent opening and closing, a must for products used daily.

In summary, each type of cosmetic plastic cover—from the basic plastic cosmetic lid to the specialized cosmetic bottle plastic cover—addresses a specific set of needs, tying directly to the product’s form, function, and user behavior. Understanding these types and their applications is essential for both consumers (to choose products that fit their lifestyle) and industry professionals (to design packaging that balances safety, usability, and appeal).

Choosing the right cosmetic plastic cover—whether it’s a plastic cosmetic lid, a cosmetic bottle plastic cover, or a transparent cosmetic plastic cover—requires more than just considering aesthetics. It involves evaluating factors that directly impact product safety, usability, and longevity. For consumers, this ensures their cosmetics stay fresh and functional; for industry professionals (such as cosmetic formulators or packaging designers), it helps avoid costly mistakes like product leakage or customer complaints. Below is a detailed breakdown of the key selection criteria for cosmetic plastic covers, along with a guide to avoiding common pitfalls.

The material of a cosmetic plastic cover directly contacts (or is in close proximity to) cosmetic products, so safety is paramount. Low-quality plastics may leach harmful substances (like BPA, phthalates, or heavy metals) into formulas—especially when exposed to heat or oily ingredients (e.g., facial oils, cream-based products). To assess material safety, focus on the following:

| Material Type | Key Characteristics | Suitable Cosmetic Plastic Cover Types | Safety Advantages |

| PP (Polypropylene) | Heat-resistant (up to 160°C), chemical-resistant, non-toxic | Plastic cosmetic lids, cosmetic bottle plastic covers (for serums/lotions) | No BPA, no phthalates; does not react with acidic or oily formulas |

| PET (Polyethylene Terephthalate) | Transparent, lightweight, shatterproof | Transparent cosmetic plastic covers, cosmetic bottle plastic covers (for toners/cleansers) | FDA-approved for food/cosmetic contact; resistant to discoloration |

| PE (Polyethylene) | Flexible, impact-resistant, moisture-proof | Cosmetic packaging covers (for travel kits), plastic makeup covers (for lip balms) | Soft texture; no chemical leaching even with repeated use |

| PS (Polystyrene, High-Impact) | Rigid, clear, cost-effective | Transparent cosmetic plastic covers (for nail polishes/lip glosses) | Non-toxic when used for dry/semi-dry products; maintains shape well |

Many low-quality cosmetic plastic covers lack clear material labels. Never purchase or use a cosmetic plastic cover that doesn’t specify its material—even if it’s affordable. For example, a "mystery plastic" cosmetic bottle cover might leach chemicals into a facial serum, ruining the formula or causing skin irritation. Always check for labels like "BPA-Free," "FDA Approved," or specific material names (e.g., "100% PP").

A cosmetic plastic cover’s functionality must align with the cosmetic it protects. A cover that works for a loose powder (e.g., a plastic cosmetic lid with a sifter) will fail for a liquid serum (which needs a leak-proof cosmetic bottle plastic cover). Below are key functional checks for different product categories:

For cosmetics used on the go (e.g., travel-sized serums, pocket lipsticks), a cosmetic plastic cover’s leak-proof and durable design is critical. A common mistake is choosing a cover that works well at home but fails in transit—for example, a cosmetic bottle plastic cover with a loose screw-on cap that leaks in a suitcase. Test travel-ready covers by:

A high-quality cosmetic plastic cover should withstand daily use—including repeated opening/closing, minor drops, and exposure to light or heat. Poor durability leads to premature wear (e.g., cracked lids, broken seals), which ruins the cosmetic inside. To evaluate durability:

Thin, flimsy plastic covers (common in low-budget options) may seem affordable, but they break easily. For example, a thin transparent cosmetic plastic cover for a nail polish bottle may crack if dropped, exposing the polish to air and causing it to thicken. Invest in covers with a minimum thickness of 0.5 mm (for flexible PE covers) or 1 mm (for rigid PP/PET covers)—these balance cost and durability.

As the beauty industry shifts toward eco-friendliness, choosing a cosmetic plastic cover that’s recyclable or reusable reduces environmental impact—without sacrificing performance. However, avoid "greenwashing" (e.g., covers labeled "eco-friendly" but made from non-recyclable materials).

Some biodegradable or recycled plastic covers lack durability or seal quality. For example, a PLA-based cosmetic bottle plastic cover may crack if exposed to oil, making it unsuitable for serums. Always test sustainable covers for functionality first—eco-friendliness should complement, not replace, safety and usability.

Before finalizing a cosmetic plastic cover (whether for personal use or professional packaging), use this checklist to ensure it meets all criteria:

By focusing on these criteria, you avoid common pitfalls and select a cosmetic plastic cover that protects your cosmetics, enhances user experience, and aligns with safety and sustainability goals—whether it’s a simple plastic makeup cover for daily use or a specialized cosmetic bottle plastic cover for a high-performance serum.

The cosmetic plastic cover—once viewed as a purely functional component of packaging—has evolved into a key driver of user experience, brand differentiation, and sustainability in the beauty industry. As consumer demands for convenience, safety, and eco-friendliness grow, manufacturers and designers are pushing the boundaries of what cosmetic plastic covers can do, integrating new technologies, materials, and design concepts. Below is an in-depth look at the latest design innovations and emerging industry trends shaping the future of cosmetic plastic covers, including advancements in types like plastic cosmetic lids, cosmetic bottle plastic covers, and transparent cosmetic plastic covers.

Modern cosmetic plastic covers are no longer just "caps"—they’re engineered to solve specific pain points, from preventing product waste to simplifying on-the-go use. These functional innovations enhance usability while maintaining the core role of protecting cosmetics.

| Innovation Type | Design Features | Suitable Cosmetic Plastic Cover Types | User Benefits |

| One-Handed Opening Mechanisms | - Snap-on lids with ergonomic ridges - Push-to-open caps (no twisting required) - Magnetic closures that align automatically |

Plastic cosmetic lids (for compacts), plastic makeup covers (for lipsticks) | Ideal for users applying makeup while multitasking (e.g., in cars or busy bathrooms); reduces fumbling with small caps |

| Controlled-Dispense Covers | - Pump caps with adjustable dosage (e.g., 0.5ml/1ml per press) - Dropper caps with built-in volume markers - Flip-top lids with "drip-free" spouts |

Cosmetic bottle plastic covers (for serums, lotions, oils) | Prevents overuse of expensive products (e.g., anti-aging serums); avoids messy spills when dispensing thick formulas |

| Dual-Purpose Covers | - Plastic cosmetic lids with integrated mirrors (for compacts) - Cosmetic bottle plastic covers that double as applicators (e.g., lip gloss wands with detachable caps) - Transparent covers with built-in product scrapers (for jarred creams) |

All types (depending on use case) | Eliminates the need for separate tools; saves space in makeup bags; reduces product waste by scraping leftover cream from jar edges |

| Child-Resistant (CR) Covers | - Screw-on caps that require "push-and-twist" activation - Snap-on lids with hidden latches |

Cosmetic bottle plastic covers (for products with harsh ingredients, e.g., chemical exfoliants) | Prevents accidental ingestion by children; meets safety standards for household products |

A standout example of this innovation is the "airless pump cover"—a type of cosmetic bottle plastic cover designed for sensitive formulas like vitamin C serums. Unlike traditional pumps that draw air into the bottle (causing oxidation), airless covers use a vacuum mechanism to dispense product, keeping the formula fresh for up to 6 months longer. This not only improves product longevity but also reduces waste by ensuring every last drop is used.

As beauty consumers increasingly prioritize "Instagrammable" packaging, cosmetic plastic covers have become a canvas for creative design—blending visual appeal with functionality. These aesthetic innovations help brands stand out on store shelves while appealing to specific consumer preferences (e.g., minimalism, luxury, playfulness).

The biggest shift in the cosmetic plastic cover industry is the move away from single-use, non-recyclable plastics toward more sustainable alternatives. These material innovations address environmental concerns (e.g., plastic waste, carbon emissions) while maintaining the durability and safety required for cosmetic packaging.

| Material Category | Composition | Key Advantages | Limitations | Suitable Cosmetic Plastic Cover Types |

| Recycled Plastics | - rPP (recycled polypropylene) - rPET (recycled polyethylene terephthalate) - PCR (post-consumer resin) blends |

- Reduces reliance on virgin plastic - Lowers carbon footprint (up to 60% less emissions than virgin plastic) - Meets global recycling standards |

- May have slight color variations - Requires careful processing to avoid contamination |

All types (plastic cosmetic lids, cosmetic bottle plastic covers, transparent covers) |

| Biodegradable Plastics | - PLA (polylactic acid, derived from corn starch) - PHA (polyhydroxyalkanoates, made from microbial fermentation) - Bio-PP (biobased polypropylene from sugarcane) |

- Breaks down in industrial composting facilities (3–6 months) - Made from renewable resources - Non-toxic, BPA-free |

- Requires specific composting conditions (not home compostable) - Less heat-resistant than virgin plastic (avoid for high-temperature storage) |

Plastic makeup covers (lip balms), cosmetic packaging covers (travel kits) |

| Hybrid Materials | - Plastic-aluminum composites (thin aluminum layer inside plastic) - Plastic-fiber blends (e.g., PP + hemp fiber) |

- Enhanced barrier properties (prevents oxygen/moisture damage) - Increased durability (hemp fiber adds strength to plastic) - Partially recyclable |

- More complex to recycle (requires separation of layers) - Slightly higher cost than pure plastic |

Cosmetic bottle plastic covers (for long-shelf-life products, e.g., sunscreen) |

A notable advancement in this space is "bio-based transparent plastic"—used for transparent cosmetic plastic covers. Unlike traditional transparent plastic (which yellows over time), bio-based versions maintain clarity while being fully biodegradable. For example, a bio-based PET cover for a lip gloss tube not only looks sleek but also breaks down completely in industrial compost, addressing the issue of plastic waste in beauty packaging.

Beyond individual innovations, broader industry trends are reshaping how cosmetic plastic covers are designed, manufactured, and used. These trends reflect the evolving needs of consumers, regulators, and brands.

The beauty industry is moving toward a "circular" model—where products and packaging are reused, recycled, or composted, rather than discarded. For cosmetic plastic covers, this means:

As "smart beauty" gains traction, cosmetic plastic covers are being integrated with technology to enhance user experience and product transparency:

Global regulators are tightening standards for cosmetic packaging, and cosmetic plastic covers are no exception. Key regulatory trends include:

Summary: The Future of Cosmetic Plastic Covers Is Functional, Sustainable, and User-First

The evolution of the cosmetic plastic cover—from a basic protective cap to a smart, sustainable, and design-forward component—reflects the beauty industry’s broader shift toward user-centricity and environmental responsibility. Functional innovations like controlled-dispense covers and airless pumps solve real user problems, while aesthetic trends turn covers into brand assets. Meanwhile, material advancements and circular economy initiatives are addressing the environmental impact of plastic packaging.

For consumers, this means access to cosmetic plastic covers that are safer, easier to use, and better for the planet—whether it’s a recycled plastic cosmetic lid for an eyeshadow palette or a biodegradable cosmetic bottle plastic cover for a serum. For industry professionals, these trends offer opportunities to differentiate products, meet regulatory demands, and align with consumer values. As innovation continues, the cosmetic plastic cover will remain a critical part of the beauty ecosystem—proving that even the "smallest" packaging components can drive big change.

The cosmetic plastic cover—often overlooked in the grand scheme of cosmetic packaging—plays an outsized role in defining how we interact with our favorite beauty products. It is not merely a "cap" or "lid" but a silent partner in preserving product efficacy, simplifying daily routines, and even reflecting our values (such as a commitment to sustainability). From the moment we unbox a new serum to the last drop of lotion we squeeze out, a high-quality cosmetic plastic cover ensures that every step of the usage journey is seamless, safe, and satisfying.

To recap, the value of a well-chosen cosmetic plastic cover lies in its ability to balance three core pillars: safety, functionality, and adaptability—traits that apply across all its variants, from plastic cosmetic lids for pressed powders to cosmetic bottle plastic covers for liquid serums. Below is a quick reference table summarizing how these pillars translate to real-world benefits for both consumers and industry professionals:

| Core Pillar of High-Quality Cosmetic Plastic Cover | Consumer Benefits | Industry Benefits (Brands/Manufacturers) |

| Safety (Non-toxic materials, BPA-free, compliant with global standards) | - No risk of chemical leaching into cosmetics - Peace of mind for sensitive skin users - Avoids product contamination |

- Meets regulatory requirements (e.g., FDA, EU Cosmetics Regulation) - Reduces liability from safety complaints - Builds long-term brand trust |

| Functionality (Leak-proof seals, easy-to-use mechanisms, durable design) | - Prevents spills during travel or daily use - Saves time (e.g., one-handed opening for busy mornings) - Minimizes product waste (e.g., airless pumps for serums) |

- Reduces returns/refunds due to packaging issues - Enhances product usability, driving repeat purchases - Differentiates products from competitors with clunky packaging |

| Adaptability (Matches cosmetic type, aligns with lifestyle, supports sustainability) | - Works for specific products (e.g., transparent covers for shade visibility) - Fits daily needs (e.g., travel-friendly lids for on-the-go touch-ups) - Aligns with eco-values (e.g., recyclable or refillable designs) |

- Flexibility to cater to diverse product lines (powders, liquids, creams) - Appeals to niche consumer groups (e.g., eco-conscious buyers, frequent travelers) - Future-proofs packaging against shifting industry trends |

For consumers, the process of choosing a high-quality cosmetic plastic cover starts with mindfulness. It means checking material labels (looking for "BPA-free" or specific safe plastics like PP/PET) before purchasing, testing functionality (e.g., shaking a liquid product to check for leaks), and considering how the cover fits their lifestyle (e.g., a magnetic plastic cosmetic lid for quick access in a purse). It also means recognizing that a slightly higher price for a durable, sustainable cover often pays off in the long run—avoiding wasted cosmetics due to poor packaging or the need to replace cheap, broken lids.

For industry professionals—whether cosmetic formulators, packaging designers, or brand managers—prioritizing high-quality cosmetic plastic covers is an investment in customer satisfaction. It means moving beyond "cost-cutting" on packaging and instead viewing the cosmetic plastic cover as a tool to enhance the overall product experience. This could involve integrating user-centric innovations (like airless pump covers for sensitive formulas) or adopting sustainable materials (like recycled rPP for plastic makeup covers) that meet both performance and environmental goals. In a crowded beauty market, where consumers have endless options, a well-designed cosmetic plastic cover can be the subtle difference that turns a one-time buyer into a loyal customer.

Looking ahead, the role of the cosmetic plastic cover will only grow in importance. As sustainability becomes non-negotiable, as smart packaging technologies become more accessible, and as consumers demand greater transparency and usability, the "ordinary" cosmetic plastic cover will continue to evolve into an extraordinary component of the beauty ecosystem. It will no longer be an afterthought but a deliberate, design-driven choice that enhances not just the product, but the lives of those who use it.

In the end, the best cosmetic plastic covers are the ones we barely notice—because they work so well. They protect our cosmetics, simplify our routines, and align with our values—all while fading into the background, letting the true star (the cosmetic itself) shine. By choosing high-quality cosmetic plastic covers, we don’t just enhance our own usage experience—we also drive demand for better, safer, more sustainable packaging across the industry. And that’s a win for everyone.

When choosing a packaging partner, prioritize factors like experience in cosmetic-specific design, quality management systems, and the ability to align with your brand’s needs (e.g., sustainability, customization). A standout option is Zhejiang Aluminum Master Packing Co., Ltd. (formerly known as Shangyu Jin Yu Packaging Co., LTD.), founded in June 2005 and located in Hangzhou Bay’s Lihai Industrial Park—an aluminum oxide production base. Situated 100 km from Shanghai and near the southern exit of the Jiashao Cross-sea Bridge, the company specializes in designing and producing various cosmetics packaging. With a total area of 18,000 square meters, a construction area of 8,000 square meters, and 200 staff, it has the scale and expertise to handle both small-batch customizations (e.g., unique plastic cosmetic lids) and large-scale production (e.g., bulk cosmetic bottle plastic covers).

Yes. The company has a complete and scientific quality management system, along with an entire line of advanced alumina processing equipment and matching tools—critical for producing high-quality cosmetic packaging, including safe, compliant cosmetic plastic covers. It adheres to strict material standards (e.g., using BPA-free, FDA-approved plastics like PP and PET) to avoid chemical leaching, and its quality checks cover every stage—from raw material inspection to final product testing (e.g., leak-proof tests for cosmetic bottle plastic covers, durability tests for plastic makeup covers). This commitment to quality aligns with the safety pillars we discussed earlier, making it a trusted partner for brands prioritizing consumer safety.

Absolutely. The company’s focus on meeting customer needs extends to sustainable and innovative packaging solutions—matching the industry trends we explored, such as recycled materials and functional innovations. Whether you need recyclable transparent cosmetic plastic covers made from rPET, or custom plastic cosmetic lids with one-handed opening mechanisms, its design and production teams can deliver. Additionally, the company’s philosophy of "excellent quality, fast delivery, quality service, and reasonable prices" ensures that sustainable or innovative designs don’t come with excessive costs or delays—helping brands stay competitive while meeting consumer demands for eco-friendly, user-centric packaging.

How Does Electrochemical Aluminum Spray Tilt Pump Technology Enhance Industrial Efficiency?

Why Aluminium Pump is the Ideal Choice for Lightweight Corrosion-Resistant Applications?

News Categories