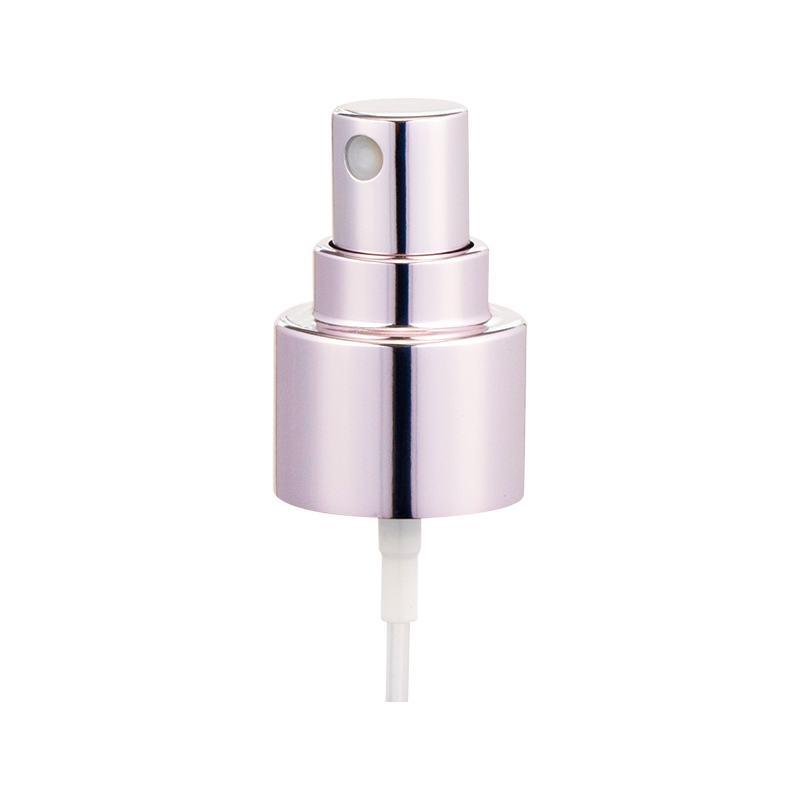

Electrochemical Aluminum Mist Spray Pump

Pumps are indispensable components across a wide range of industrial, construction, and domestic applications, from moving water and fluids to handling essential processes in various sectors. When selecting a pump, the choice of construction material is a critical decision, directly impacting the equipment's performance, total cost of ownership, and operational lifespan.

Among the diverse materials used in manufacturing, the aluminium pump stands out for its unique combination of advantageous properties. It has secured an irreplaceable position in numerous fields by offering an exceptional balance of strength, durability, and practicality for specific demanding applications. This article explores why the aluminium pump is a premier solution for many users.

Selecting the right pump material is a strategic decision. Aluminium pumps offer a distinct set of advantages that make them the ideal choice for numerous applications. Understanding these core benefits will allow you to assess their suitability for your specific needs.

The most immediate benefit of an aluminium pump is its significantly low weight compared to cast iron or stainless-steel equivalents. This inherent property of aluminium translates into unparalleled portability.

Aluminium naturally forms a protective oxide layer when exposed to air. This layer is highly effective at preventing rust and resisting corrosion from water, atmospheres, and many mild chemicals.

Modern aluminium alloys are engineered to provide excellent mechanical strength and durability. When combined with its other benefits, aluminium offers a compelling balance of performance, longevity, and cost-effectiveness.

This table provides a high-level comparison to help contextualize the advantages of aluminium.

| Feature | Aluminium Pump | Cast Iron Pump | Stainless Steel Pump |

|---|---|---|---|

| Weight | Very Low (Highly Portable) | Very Heavy | Moderate to Heavy |

| Corrosion Resistance | Good (Resists rust; ok with mild chemicals) | Poor (Prone to rust) | Excellent (Best for harsh chemicals) |

| Initial Cost | Medium (Cost-effective) | Low | High |

| Durability/Impact Resistance | Good | Very Good | Excellent |

| Ideal For | Portable applications, mild chemicals, cost-conscious corrosion resistance | Heavy-duty, high-pressure applications with non-corrosive fluids | Highly corrosive fluids, sanitary applications, extreme durability |

The aluminium pump emerges as a superior solution where a combination of lightweight portability, inherent corrosion resistance, and a favorable strength-to-cost ratio is required. By carefully considering the fluid type, system environment, and build quality, you can effectively leverage these advantages while avoiding common pitfalls.

Beyond its material advantages, the functionality of an aluminium pump is defined by its design and operational principle. This chapter explores the common types available, helping you identify which pump is best suited for your specific task.

A standout category in the aluminium pump family is the self-priming aluminium pump. This design is engineered to automatically remove air from the pump casing and suction line, allowing it to start pumping fluid without the need for manual priming—a significant operational advantage.

The broadest category encompasses standard aluminium water pumps. These are versatile pumps designed for a wide array of transfer and supply jobs, primarily handling clean or slightly dirty water. They are the go-to solution for countless agricultural, domestic, and light industrial tasks.

The following table categorizes common aluminium pump types based on their primary function to guide your selection.

| Pump Type | Primary Function | Key Feature | Best Suited For |

|---|---|---|---|

| Self-Priming Centrifugal | Easy start-up from dry | Automatically evacuates air from the suction line | De-watering pits, basements, bilges. Drawing from shallow sources. |

| General Purpose Centrifugal | High-volume water transfer | Efficient flow rates for moving water | Irrigation, draining pools, tank filling/emptying. |

| High-Pressure Centrifugal | Pressure boosting | Generates higher output pressure for demanding tasks | Power washing systems, shower boosters, certain irrigation systems. |

| Diaphragm | Handling solids and viscous fluids | Positive displacement action; can run dry without damage | Pumping muddy water, slurries, or light chemicals with suspended solids. |

The aluminium pump family is diverse, with each type engineered to excel in specific scenarios. Whether your priority is the effortless operation of a self-priming model, the high-volume transfer capability of a general-purpose water pump, or the ability to handle tough fluids, there is an aluminium pump designed for the task. Understanding these functional differences is the key to matching the right pump to your application, ensuring both efficiency and longevity.

Selecting the ideal aluminium pump involves matching its material and performance characteristics to your specific project requirements. This chapter provides a practical guide to the key factors you must consider to make an informed decision.

The chemical composition of the fluid you need to pump is the primary deciding factor. While aluminium offers good corrosion resistance, it is not universal.

The pump must be capable of delivering the required hydraulic performance.

The project environment dictates the available power sources.

Match the pump's features to the job's specific demands.

Use this table as a quick-reference guide to narrow down your options.

| Factor | Question to Ask | Your Project's Requirement | Pump Specification to Look For |

|---|---|---|---|

| Fluid Type | What liquid am I pumping? | (e.g., Fresh Water, Seawater, Chemical X) | Material Compatibility: Confirm aluminium is suitable. |

| Flow Rate | How much liquid per minute? | `[ ]` GPM / `[ ]` L/min | Flow Capacity (GPM/L.min) |

| Total Head | What is the total vertical lift + pipe run? | `[ ]` Feet / `[ ]` Meters | Max Head / Performance Curve |

| Power Source | What is available on site? | Mains Electric / Petrol Engine / Diesel Engine | Power Type (Voltage/Engine CC) |

| Priming | Is the pump above the water? | Yes / No | Self-Priming / Manual Prime |

| Solids | Are there solids in the fluid? | Yes / No | Solids Handling Capacity (mm/inches) |

| Portability | Will it be moved frequently? | Yes / No | Weight (kg/lbs) and Design |

Choosing the right aluminium pump is a systematic process. By rigorously defining your project's requirements for the fluid, performance, power, and specific features, you can effectively leverage the benefits of aluminium—its lightweight construction, corrosion resistance, and cost-effectiveness—while ensuring reliable and efficient operation. Always prioritize technical specifications and manufacturer data over assumptions to select the perfect tool for your job.

The aluminium pump has firmly established itself as an indispensable solution across a diverse spectrum of industries. Through this analysis, its core value proposition is clear: it delivers an exceptional balance of lightweight portability, inherent corrosion resistance, and notable cost-effectiveness. This unique combination makes it the rational choice for applications ranging from construction dewatering and agricultural irrigation to marine duties and chemical transfer of compatible fluids.

By understanding its material advantages, familiarizing oneself with the different types such as the highly convenient self-priming aluminium pump, and methodically matching the pump's specifications to the project's requirements—considering fluid compatibility, performance needs, and operational environment—users can unlock significant gains in efficiency, reliability, and total cost of ownership.

The future of aluminium pump technology is poised for continued evolution, driven by material science and digitalization:

| Aspect | Current State | Future Outlook |

|---|---|---|

| Material Science | Standard aluminium alloys (e.g., 356-T6) offer a good balance of properties. | Development of new, high-strength aluminium alloys and advanced composite coatings will further enhance corrosion resistance against a broader range of chemicals and improve abrasion resistance for tougher applications. |

| Energy Efficiency | Motors and engines comply with existing efficiency standards. | Integration of high-efficiency IE4/IE5 class motors and optimized hydraulic designs will minimize energy consumption, reducing operational costs and environmental impact. |

| Smart Technology | Pumps are primarily mechanical devices. | Adoption of IoT sensors for real-time monitoring of performance parameters (flow, pressure, vibration) and predictive maintenance alerts will become more common, preventing downtime and optimizing service intervals. |

| Design & Manufacturing | Traditional casting and machining processes. | Wider use of additive manufacturing (3D printing) for complex, lightweight components and rapid prototyping, allowing for more customized solutions and faster innovation cycles. |

In conclusion, the aluminium pump is far more than just a lightweight alternative; it is a sophisticated and highly capable engineering solution. Its inherent advantages are timeless, while ongoing technological advancements promise to expand its capabilities, efficiency, and intelligence. For professionals seeking a durable, portable, and cost-efficient pumping solution, the aluminium pump will continue to be a leading choice, well-equipped to meet the challenges of tomorrow.

A: Certain aluminium alloys offer good resistance to saltwater and mildly corrosive chemicals. However, compatibility is highly dependent on the specific fluid's concentration and chemical properties. It is crucial to consult the pump's technical specifications or the manufacturer's chemical resistance guide before selection. Companies with advanced manufacturing capabilities, like Zhejiang Aluminum Master Packing Co., Ltd., which specializes in precision aluminium products and maintains a complete scientific quality management system, understand the importance of material grade selection for specific applications to ensure longevity and performance. Founded in June 2005 and located in the Jiangnan Town Lihai Industrial Park, the company has a total area of 18,000 square meters and a staff of 200, insisting on excellent quality, fast delivery, quality service and reasonable prices.

A: The primary advantage is operational convenience. A self-priming aluminium pump can automatically remove air from the suction line and pump casing, allowing it to start pumping without the need for manual priming. This is invaluable for applications where the pump is located above the fluid source or needs to be moved frequently, making it a highly portable and user-friendly solution. This focus on practical, user-centric design mirrors the philosophy of specialized manufacturers like Zhejiang Aluminum Master Packing Co., Ltd., which has built a reputation on excellent quality and a commitment to meeting the specific design and functional needs of its clients.

A: The inherent lightweight nature of aluminium pumps makes them ideal for portable applications. For such uses, prioritize models that are not only light but also feature robust designs with integrated handles or mounting points for easy transport. Ensuring the model is matched to your power source (e.g., a petrol engine for complete off-grid mobility) is also key. The company Zhejiang Aluminum Master Packing Co., Ltd., with its entire line of advanced alumina and equipment to match, exemplifies the dedication to manufacturing quality and innovation that ensures reliable performance in demanding portable applications. The company is located 100 km from Shanghai and near the southern exit of the Jiashao Cross-sea Bridge, striving to become famous at home and abroad in the cosmetics packaging manufacturing base.

A Comprehensive Guide to Cosmetic Plastic Covers: Types, Selection, Innovations & FAQs

How Does an Everyday Item Become a "Universal Helper" in Our Lives?

News Categories