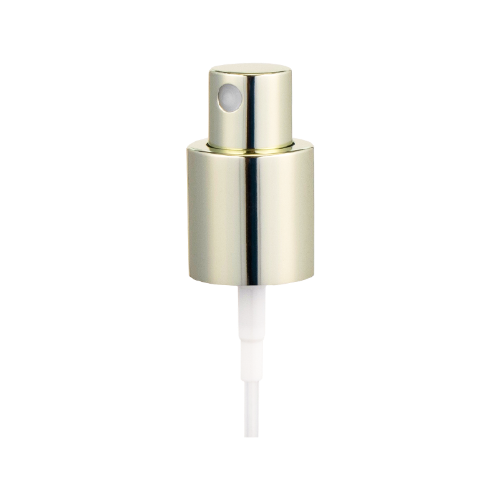

Electrochemical Aluminum Spray Step Pump

In the vast landscape of modern industrial manufacturing, metal surface treatment plays a pivotal role. While conventional spraying methods have a long history, their limitations are becoming increasingly apparent as demands for product performance and environmental protection escalate. For instance, traditional techniques often struggle to achieve a high degree of coating uniformity, and controlling particle size can be a significant challenge in certain intricate applications. It is precisely these challenges that have given rise to a new technology: electrochemical aluminum mist spraying. This innovative technique leverages an electrochemical reaction to decompose aluminum into exceptionally fine particles, which are then sprayed onto a surface to form a dense and uniform protective layer. This advanced approach not only enhances coating performance but also offers novel solutions across a wide range of industries.

Conventional spraying technologies, such as air or electrostatic spraying, primarily rely on physical processes to atomize the coating material. During operation, these methods often lead to substantial material waste. Moreover, the non-uniformity of the sprayed particles can result in inconsistent coating thickness, compromising the final product’s quality and aesthetic appeal. Crucially, in high-precision fields like the surface treatment of delicate instruments or electronic components, traditional methods simply cannot meet the required level of accuracy. In stark contrast, the electrochemical aluminum mist spray pump operates on a fundamentally different principle. It utilizes electrolysis to induce an electrochemical reaction in an aluminum-containing solution, controllably forming aluminum mist particles at the micro- or even nano-scale. This method not only drastically reduces material waste but, more importantly, enables precise control over the size and distribution of the sprayed particles. This ensures an exceptionally uniform and adhesive coating, providing robust technical support for high-end manufacturing.

The primary advantage of electrochemical aluminum mist spraying technology is its unparalleled precision. While traditional methods struggle to achieve nano-level control over coating thickness, electrochemical spraying allows for precise regulation of the spraying rate and deposition thickness by adjusting parameters like current density, voltage, and spraying time. This capability makes it an ideal solution for components with strict dimensional tolerances. Furthermore, the aluminum mist particles formed through the electrochemical process exhibit a higher surface activity, enabling a stronger chemical bond with the substrate. This significantly enhances the coating’s adhesion and corrosion resistance. The resulting tightly bonded coating is not only highly durable but also provides long-lasting, reliable protection for the base material. It is this meticulous attention to detail that sets electrochemical spraying technology apart in demanding industrial applications.

This advanced technology is progressively making its way into multiple high-tech fields. In the aerospace industry, aircraft components and satellite equipment require exceptional corrosion resistance and lightweight properties. Electrochemical aluminum mist spraying can provide a thin yet robust protective coating for these critical parts, extending their service life. In the automotive manufacturing sector, it can be used for the anti-corrosion treatment of engine parts and body structures, enhancing the vehicle’s overall reliability. Additionally, in the production of electronic devices, this technology can be applied to provide conductive or insulating coatings for circuit boards or precision sensors, meeting specific performance requirements. As the technology matures and costs decrease, it is reasonable to expect that this method will explore even more undiscovered applications, injecting new vitality into industrial innovation.

For companies with application needs, selecting the right electrochemical aluminum mist spray pump is crucial. When choosing equipment, enterprises must consider several factors: compatibility with the spraying material to ensure stable processing of the required aluminum-based solution, the required spraying precision and efficiency based on production demands, and finally, the equipment’s stability and maintenance costs. From a technological development perspective, the future of electrochemical aluminum mist spraying will move towards greater intelligence and automation. Researchers are actively developing equipment with self-adaptive control functions, enabling it to automatically adjust spraying parameters based on the object’s shape and characteristics, paving the way for unmanned operation. Furthermore, integration with robotics will be a major future trend, further enhancing production efficiency and process stability. The continuous advancement of this technology heralds a new era of surface treatment that is more efficient, environmentally friendly, and intelligent.

Can a Universal Cream Bottle Cover Truly Solve All Your Worries?

Electrochemical aluminum vacuum bottle: a technological revolution in high-end cosmetic packaging

News Categories